Welcome to S. K. Engineering Works

Trader & Supplier of:

We deal in a wide range of Chemical & Pharmaceutical Equipment, including:

ANF / ANFD

ANF ANFD

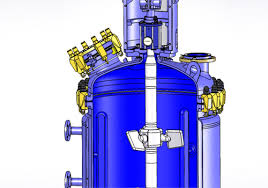

ANF (Agitated Nutsche Filter) and ANFD (Agitated Nutsche Filter Dryer) motors are specially designed drive systems used to operate the agitator mechanism inside these chemical process equipment units. They play a crucial role in filtration, solid–liquid separation, washing, and drying operations in industries such as pharmaceuticals, chemicals, agrochemicals, and dyes.

Types of Motors Used

Flameproof Motors: Common in chemical plants where hazardous and explosive vapors may be present.

What We Offer

Our Services

All Types of Scraps

Heavy Melting Scrap (HMS): Industrial cuttings, beams, rails, plates, and machinery parts.

Cast Iron Scrap: Broken engine blocks, machine bases, and other cast products.

Steel Scrap: Sheets, coils, structural steel from construction, pipelines, and shipbreaking.

Shredded Steel Scrap: Derived from shredded vehicles and appliances, cleaned of non-metallic parts.

ANF (Agitated Nutsche Filter) and ANFD (Agitated Nutsche Filter Dryer)

motors are specially designed drive systems used to operate the agitator mechanism inside these chemical process equipment units. They play a crucial role in filtration, solid–liquid separation, washing, and drying operations in industries such as pharmaceuticals, chemicals, agrochemicals, and dyes.

Chemical Process Equipment

Used for mixing, reacting, heating, cooling, and transferring materials.

a. Reactors

SS Reactors (316/316L/304): For general chemical reactions under pressure or vacuum.

Glass-Lined Reactors: For corrosive chemicals and APIs.

Filter Press

A filter press is a mechanical device used to separate solids from liquids by using pressure filtration. The slurry (liquid with suspended solids) is pumped into the press, and pressure forces the liquid through filter media, leaving the solid particles behind as a cake.

HDPE (High-Density Polyethylene) Equipment

HDPE is a thermoplastic polymer known for high chemical resistance, impact strength, and lightweight properties.

Glass-Lined Reactors (GLR)

Glass-lined reactors are chemical reactors coated internally with borosilicate or other chemical-resistant glass to provide corrosion resistance, smooth surface, and easy cleaning, making them ideal for chemical and pharmaceutical processes.

Our Story

See How We Transform Ideas Into Reality!

Our Work

Portfolio Showcase

SS & MS Storage Tank RVD RCVD

OLD MOTOR

SS & MS Reactors

SS CENTRIFUGES

STAINLESS STELL SS & MILD STELL MS Reactors

HDPE PP & FRP EQUIPMENT

20

+

Winning Award

100K

+

Happy Customers

20M

+

Working Hours

100

+

Completed Projects

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quas voluptatem maiores eaque similique non

Watch Intro

core values

We build everything you need

Material of Construction: Mild steel or carbon steel body with internal glass lining (~1–3 mm thick).

Storage Tanks: Cylindrical, vertical or horizontal; capacities from 50 L to 50,000 L+.

MIXING TANKS

With agitators for blending chemicals

CONICAL BOTTOM TANKS

For complete drainage of slurry or liquids.

Dosing Tanks

For precise chemical addition.

Pipes & Fittings

HDPE piping for chemical transfer, resistant to corrosion and scaling.

This Training is supported by

What People say about Us

Selvaraj Pillai and Karan Pillai have been instrumental in creating significant business value across the pharmaceutical and other leading industries for the past four decades. Their visionary leadership, deep technical expertise, and commitment to excellence have helped numerous organizations achieve operational efficiency, innovation, and sustained growth. Over the years, they have successfully guided projects, implemented advanced technologies, and built strong client relationships, establishing themselves as trusted leaders in the industry.

Mahesh

VAPI

No results